Electric motors are at the heart of modern industry, powering everything from household appliances to industrial machinery. But before the sleek, efficient motors we rely on today, pioneers were experimenting with fundamental principles of electricity and motion. One such invention, Barlow’s Wheel, may seem like a simple 19th-century experiment, yet its influence resonates with today’s experienced equipment mechanics, industrial mechanics and even modern manufacturing practices.

A Glimpse into History: Barlow’s Wheel

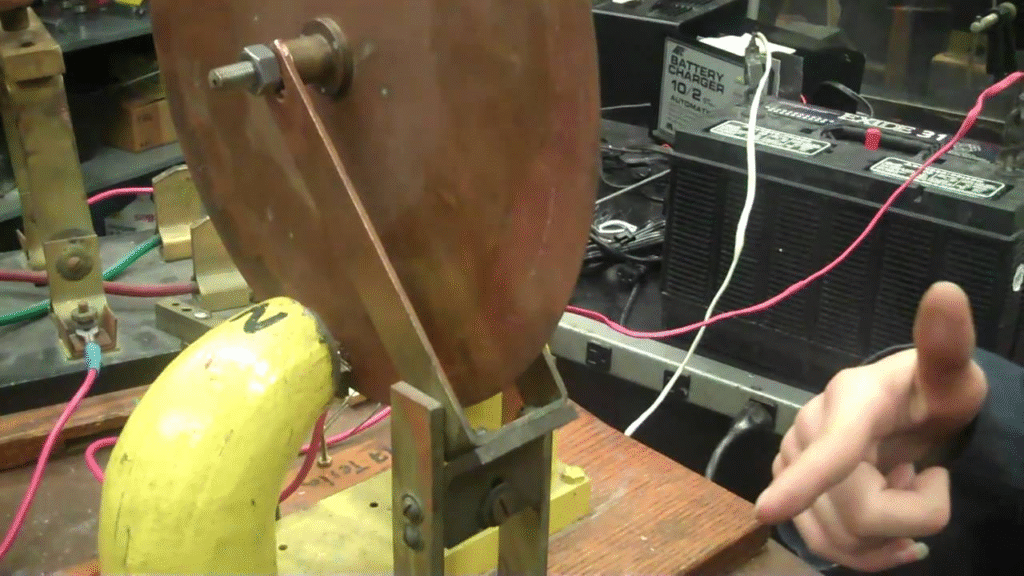

Invented in 1822 by Peter Barlow, Barlow’s Wheel was an early demonstration of electromagnetic rotation. Essentially, it consisted of a metal wheel that rotated when an electric current passed through it in the presence of a magnetic field. While it might seem like a basic classroom experiment now, at the time, it was revolutionary—it showed a tangible connection between electricity and mechanical motion.

This experiment laid the foundation for later advances in electric motors. Engineers and mechanics studying Barlow’s Wheel were able to understand how electric current could generate continuous rotational motion, which is the principle behind nearly all electric motors today.

Modern Applications of Barlow’s Wheel Concepts

You might wonder, “How does a 200-year-old experiment relate to today’s hiring for electrical assemblers in Chicago or the work of a skilled electromechanic?” The connection is closer than it seems. While Barlow’s Wheel itself isn’t used in production lines, the principles of electromagnetism it demonstrates are applied in several ways:

- Motor Diagnostics

Experienced mechanics often use foundational knowledge inspired by Barlow’s Wheel when troubleshooting motors. Understanding the interaction between current and magnetic fields helps mechanics pinpoint problems in electric motors, from industrial machines to electric vehicles. - Education and Training

Many vocational programs use Barlow’s Wheel as an introductory tool to teach students about electromagnetism and motor function. For young electrical assemblers learning the ropes in cities like Chicago, seeing the principles in action bridges the gap between theory and practice. - Prototype Development

Small-scale motor prototypes often rely on simple rotational experiments inspired by Barlow’s Wheel. Designers testing new electromagnetic materials or coil configurations sometimes recreate the wheel’s conditions to visualize how current will interact with magnets before scaling up to full motor assemblies. - Museum and Maker Spaces

Beyond industrial applications, Barlow’s Wheel has found a home in museums and maker workshops, inspiring engineers and hobbyists alike. Its visual demonstration of electricity and motion sparks curiosity and innovation, which in turn influences real-world designs.

The Role of Experienced Electric Motor Mechanics

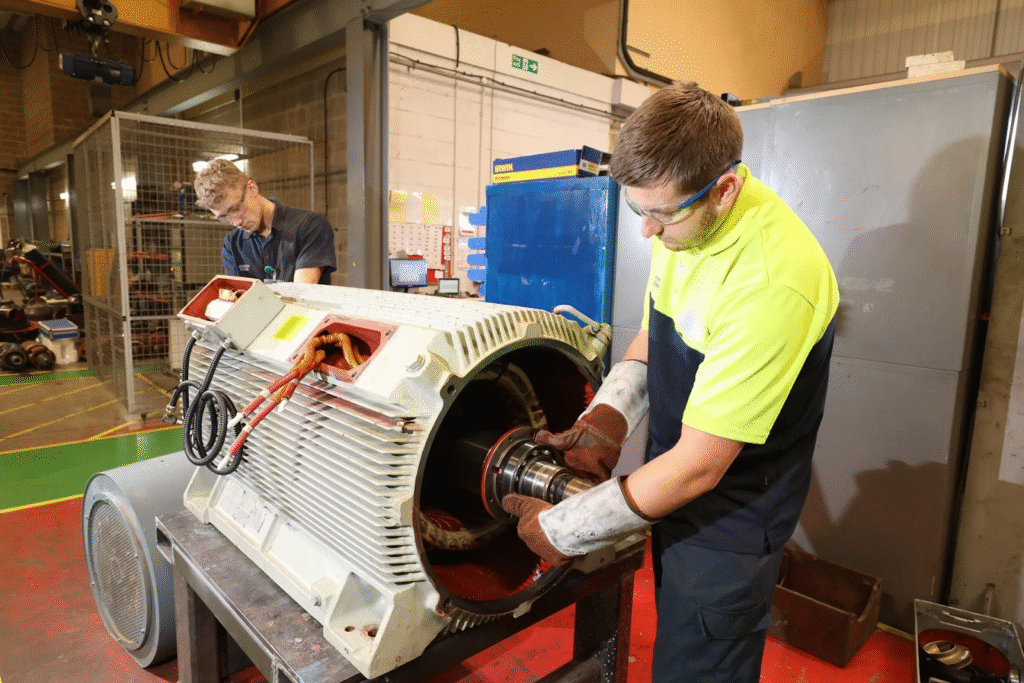

Today’s industrial landscape depends on professionals who can take these centuries-old concepts and apply them to cutting-edge technology. Experienced electric motor mechanics are invaluable because they understand both the history and the modern application of electromagnetism.

Mechanics working in workshops, factories, or even research labs often encounter situations where troubleshooting isn’t just about following a manual. They need to visualize how current flows, how magnetic fields interact, and how small adjustments can dramatically affect motor performance. This hands-on understanding, grounded in principles demonstrated by experiments like Barlow’s Wheel, is why experienced mechanics remain in high demand.

In cities like Kansas City, Sioux Falls and Chicago, there is also a growing need for skilled workers in production environments. Businesses are often recruiting for electrical and mechanical assemblers, seeking candidates who can assemble, maintain, and troubleshoot complex electromechanical equipment. Having a workforce familiar with fundamental concepts of electromagnetism ensures higher quality and efficiency on the shop floor.

Bridging the Gap Between Education and Industry

Barlow’s Wheel also serves as an educational bridge. Modern vocational schools often integrate interactive demonstrations alongside technical training. For example, a student may start by observing the wheel’s rotation and then move on to assembling real motors with guidance from instructors. This method helps students internalize how theoretical concepts apply to tangible machinery.

Furthermore, training programs can help address workforce shortages. In the U.S., manufacturing hubs like Chicago actively seek skilled assemblers who are not only technically competent but also understand the “why” behind the machinery. By linking foundational experiments to practical applications, schools and employers are creating a pipeline of proficient workers ready to tackle the demands of modern industry.

Innovation Inspired by Simplicity

One of the remarkable lessons from Barlow’s Wheel is that innovation often begins with simplicity. The wheel itself is a straightforward device, yet it encapsulates the core principles of electromagnetic rotation that underpin all modern motors. This simplicity inspires mechanics and engineers to experiment, iterate, and innovate—qualities that are crucial in today’s rapidly evolving industrial landscape.

In workshops across the country, mechanics may not recreate Barlow’s Wheel daily, but the mindset it encourages—curiosity, experimentation, and understanding fundamental principles—remains central. Whether fine-tuning a high-voltage motor or optimizing an assembly line, the conceptual lessons of the wheel continue to guide decisions.

Looking Forward: The Future of Motor Mechanics

As technology advances, the role of the electric motor mechanic is evolving. Automation, robotics, and AI-assisted diagnostics are changing the tools and methods used in workshops. However, the foundational knowledge symbolized by Barlow’s Wheel remains essential. Mechanics who grasp these basics are better equipped to adapt to emerging technologies, troubleshoot complex systems, and innovate within their field.

Employers looking to strengthen their workforce—especially those hiring for electrical assemblers in Chicago—can benefit by emphasizing training that connects theory with hands-on experience. By understanding the principles demonstrated by Barlow’s Wheel, new hires can accelerate their learning curve and contribute more effectively to production goals.

Conclusion

From its origins as a 19th-century classroom experiment to its subtle influence on modern motor diagnostics and education, Barlow’s Wheel exemplifies how foundational experiments can inspire generations of engineers and mechanics. For today’s certified electromechanics, it serves as a reminder that even the simplest demonstrations of physics can inform complex industrial applications.

Whether in training programs, prototype development, or the daily work of assembling and maintaining motors, the legacy of Barlow’s Wheel endures. Its principles continue to guide innovation, ensuring that the next generation of mechanics remains capable, curious, and inspired.