Introduction

In the world of modern hydroelectric power, the Francis Turbine stands out as one of the most efficient and widely used designs. Developed in the 19th century by James B. Francis, this mixed-flow turbine plays a crucial role in converting water’s kinetic and potential energy into mechanical and then electrical power.

This article explores the Francis Turbine impact on electrical power generation, focusing on how experienced generator technicians and licensed professionals improve efficiency and reliability. It also includes terminology, visuals, and graph placeholders to better explain key concepts.

1. Understanding the Francis Turbine

A Francis Turbine is a reaction turbine that operates under medium water head (10–650 meters) and variable flow conditions. It efficiently converts water pressure and velocity into mechanical energy that drives an electrical generator.

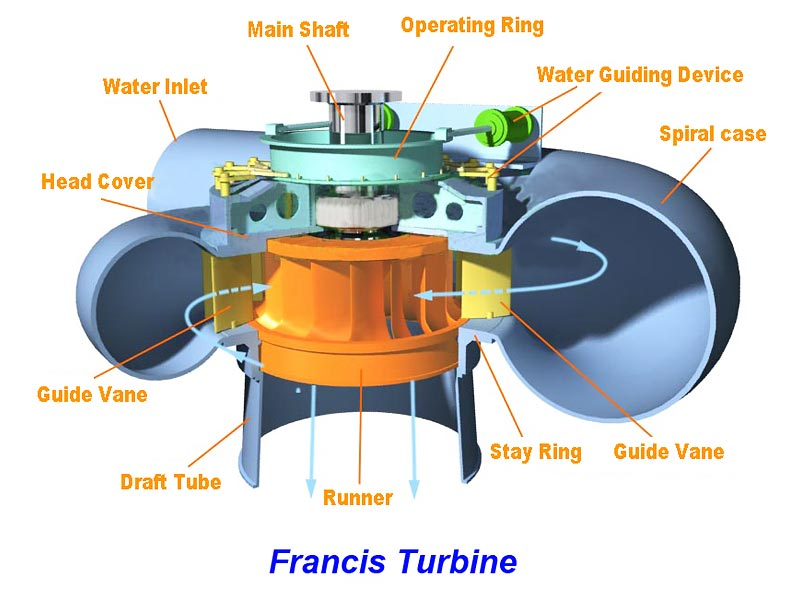

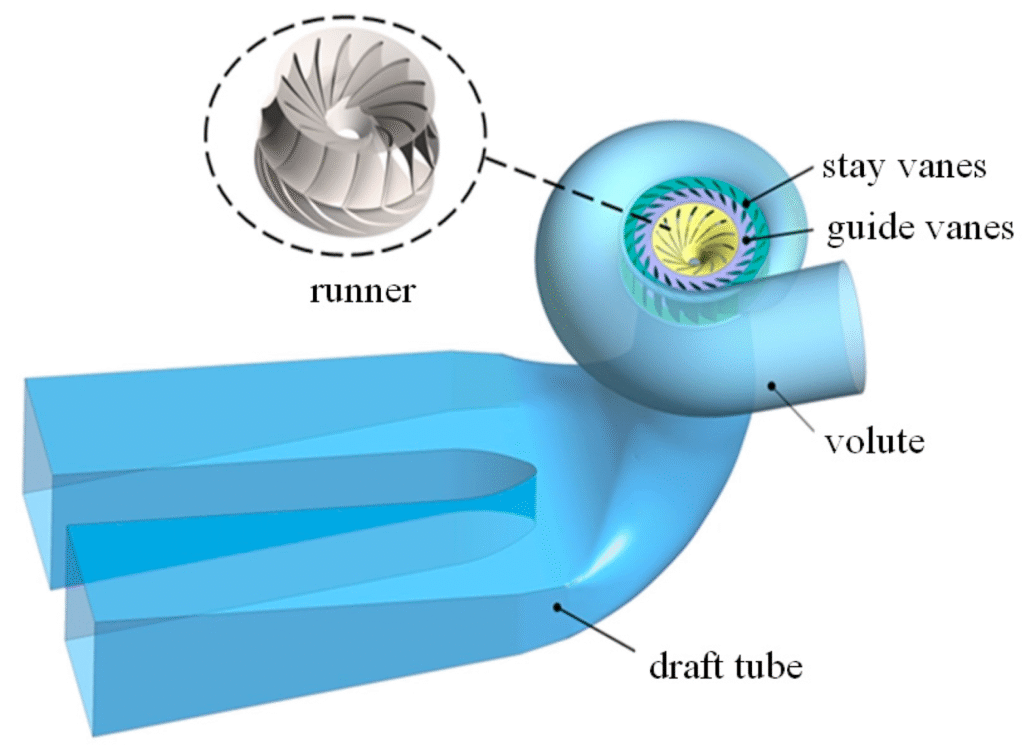

Key Components (Terminology Section):

- Runner Blades: Curved blades that rotate when water flows through the turbine.

- Guide Vanes: Adjustable vanes controlling water flow and direction entering the runner.

- Spiral Casing: A circular chamber that evenly distributes water around the runner.

- Draft Tube: A pipe that discharges water and recovers pressure energy.

- Shaft and Coupling: Mechanical components transferring rotational energy to the generator.

This combination ensures smooth operation and high efficiency under changing loads, making the Francis Turbine the most common turbine type in hydroelectric plants worldwide.

2. The Role of the Francis Turbine in Electrical Power Generation

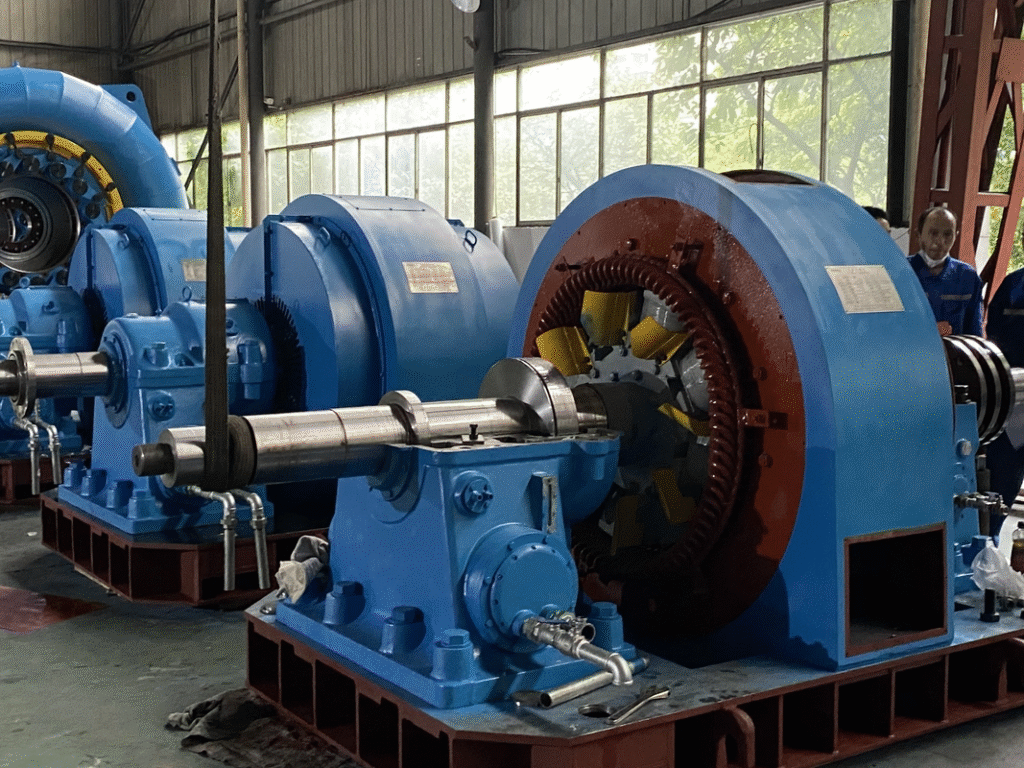

When water passes through the Francis Turbine, it spins the runner, which turns the generator shaft. This rotation produces electricity through Faraday’s Law of electromagnetic induction.

Hydroelectric power plants using Francis Turbines can generate from 10 MW to more than 800 MW, depending on the water head and plant design.

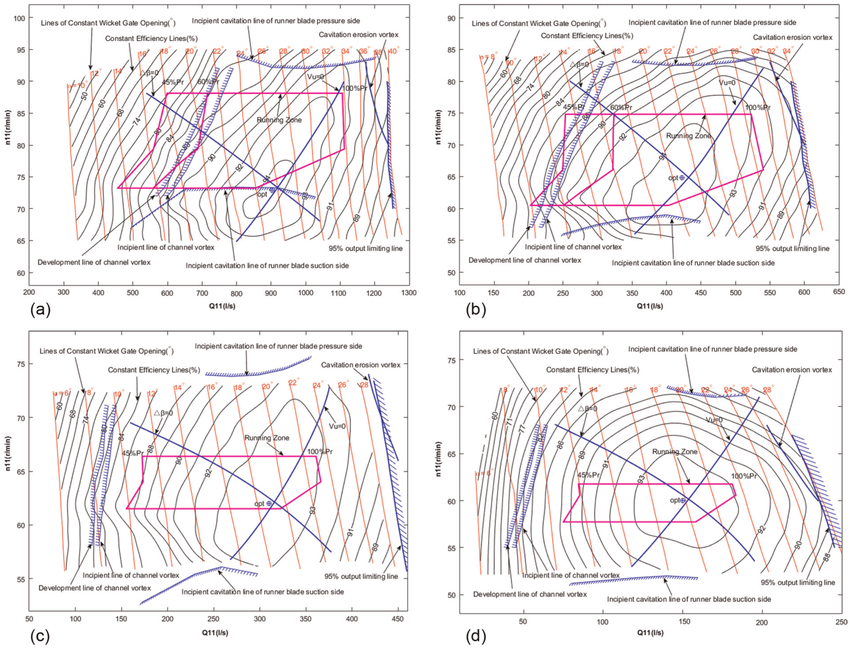

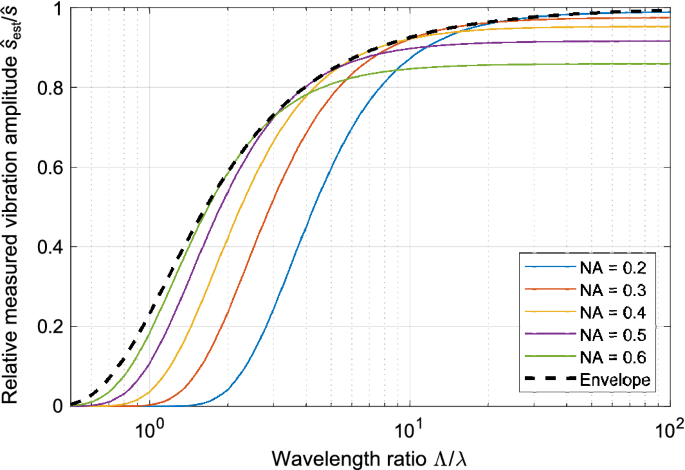

Graph :

This graph demonstrates that the Francis Turbine maintains more than 90% efficiency across a wide range of flow conditions, a key reason it is favored over impulse turbines.

3. Efficiency Factors Influenced by Generator Technicians

The turbine’s design ensures efficient energy conversion, but its real-world performance depends on the skill and precision of experienced generator technicians. Their expertise keeps turbines operating at peak performance and minimizes downtime.

Technicians’ Key Responsibilities:

- Perform precise turbine-to-generator alignment to prevent vibration losses.

- Adjust guide vanes for maximum hydraulic efficiency.

- Maintain and lubricate bearings to reduce friction and wear.

- Optimize electrical load balancing and test generator insulation resistance.

- Conduct regular vibration and temperature monitoring for predictive maintenance.

These steps significantly enhance the Francis Turbine impact on electrical power generation and extend the system’s operational life.

4. Why Licensed Generator Technicians Matter

Working on hydroelectric systems requires technical certification, safety awareness, and regulatory compliance. A licensed generator technician ensures these standards are met while maintaining optimal performance.

Where to Find Licensed Generator Technicians:

- Hydropower Contractors: Many large-scale EPC (Engineering, Procurement, Construction) companies employ certified professionals.

- Technical Associations: Organizations like IEEE, IEC, or local energy boards provide directories of certified technicians.

- Professional Networks: Job portals such as LinkedIn, GeneratorTechnicianJobs.com and Indeed feature profiles of licensed generator specialists.

- Training Institutions: Graduates from accredited hydropower or electrical engineering programs often hold relevant licenses.

Hiring licensed experts guarantees reliable turbine operation, safety compliance, and long-term cost efficiency.

5. The Engineering Advantage of the Francis Turbine

Compared to other turbine designs, the Francis Turbine offers superior adaptability and performance under medium head and variable flow conditions.

Performance Highlights:

- Operates efficiently under water heads between 10 and 650 meters.

- Achieves efficiency levels of 85–95%, higher than most turbine types.

- Works with a mixed-flow pattern (radial plus axial), providing smoother energy transfer.

- Offers excellent speed regulation, ideal for grid-connected systems.

- Outperforms impulse turbines in versatility and flow control.

Because of these features, the Francis Turbine remains the backbone of modern hydroelectric power stations.

6. Maintenance and Predictive Monitoring

Regular inspection and predictive maintenance are vital for ensuring turbine efficiency. Experienced generator technicians use advanced monitoring tools to prevent failures before they occur.

Common Maintenance and Monitoring Tasks:

- Vibration Analysis: Detects imbalance or bearing wear.

- Oil and Temperature Monitoring: Ensures safe operating conditions.

- Digital Twin Simulation: Uses virtual models to predict turbine performance.

- Blade Imaging and Inspection: Identifies early-stage erosion or cavitation.

- Electrical System Testing: Monitors generator load, frequency, and power factor.

By combining these techniques, technicians reduce downtime and extend the turbine’s lifespan, strengthening the Francis Turbine’s impact on electrical power generation.

7. Environmental and Economic Benefits

The Francis Turbine not only delivers power efficiently but also supports global sustainability goals.

Major Benefits Include:

- Zero Emissions: Generates electricity without burning fossil fuels.

- Longevity: Can operate for 30–50 years with proper maintenance.

- Employment Opportunities: Creates demand for licensed generator technicians and engineers.

- Economic Stability: Provides consistent power output, unlike intermittent renewable sources.

- Grid Reliability: Maintains steady voltage and frequency for regional power networks.

Governments are investing heavily in modernizing old plants with new-generation Francis Turbines, ensuring cleaner and more stable energy production.

8. Future Trends in Turbine Technology

As the renewable energy sector evolves, Francis Turbine technology is advancing toward smarter, more efficient systems.

Emerging Developments:

- Smart Sensors: Monitor flow, temperature, and vibration in real time.

- AI-Based Control Systems: Optimize guide vane angles for peak efficiency.

- Eco-Friendly Materials: Reduce corrosion and improve lifespan.

- Remote Diagnostics: Enable technicians to detect faults without shutdowns.

- Hybrid Expertise: Future technicians will need mechanical, electrical, and digital knowledge.

By 2030, nearly 40% of new hydro projects are expected to include intelligent turbine systems, increasing the role of licensed generator technicians worldwide.

Conclusion

The Francis Turbine continues to dominate hydroelectric power generation due to its versatility, efficiency, and reliability. However, the true success of these systems relies on the expertise of experienced and licensed generator technicians who ensure proper installation, alignment, and maintenance.

Their technical skill directly enhances the Francis Turbine’s impact on electrical power generation, making it a cornerstone of sustainable energy production. As hydropower plants modernize, combining technical know-how, predictive monitoring, and innovative design will ensure a cleaner and more efficient energy future for generations to come.